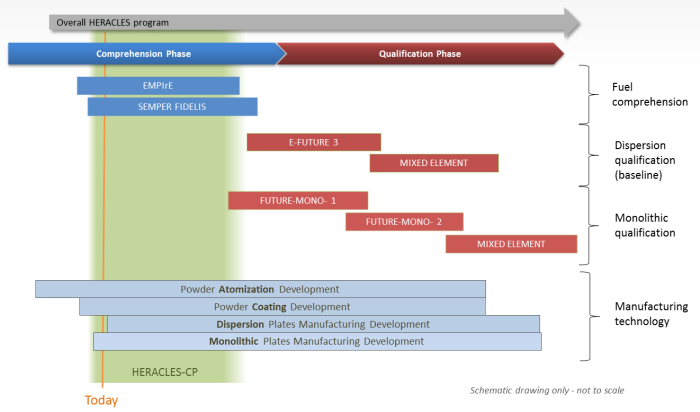

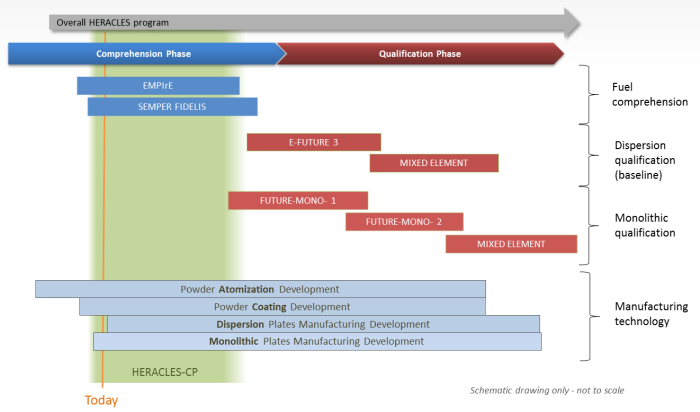

As regards the manufacturing equipment required for dispersion and monolithic fuel, HERACLES follows an evolutionary approach,

using prototype (1% of commercial production capacity), pilot (10% capacity) and commercial (100% capacity) equipment for each

technology, in order to reduce the risks when transferring from laboratory to industrial scale. The prototype equipment is already

available and will be used for sample plate experiments (EMPIRE and SEMPER FIDELIS, WP6) and for the manufacturing requirements of

the first full-size plate experiments, marking the beginning of the qualification phase (SELENIUM 2 and FUTURE-MONO I). The pilot

equipment will be used for the second full-size plate experiments (E-FUTURE III and FUTURE-MONO II) and mixed element or/and DDE

experiment manufacturing. Finally, the commercial equipment will be constructed after the results of the first full-size plate

irradiation experiments and will be used for LTA (Lead Test Assembly) and commercial production.

Dispersion fuel manufacturing

Powder atomization

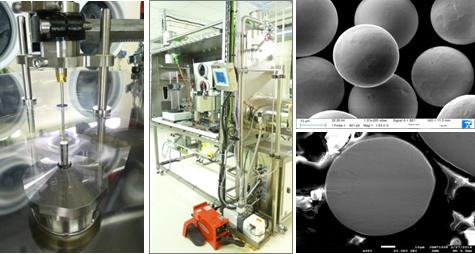

3 types of powder atomization technology are currently used world-wide for UMo powder production: Centrifugation with a rotating disk

(KAERI), centrifugation with a rotating electrode process (REP, used by TUM / Framatome (CERCA), INL, ANL, NCCP, CCEN technology) and powder

from machining (AECL technology). Regarding irradiation performance, the Fuel Developer Expert Group (FDEG) believes that the production

technology has no major influence. An analysis carried out by the Fuel Manufacturer Expert Group (FMEG) concluded that the REP technology

was the most promising candidate, especially taking into account the safety requirements of the French fuel manufacturer Framatome (CERCA).

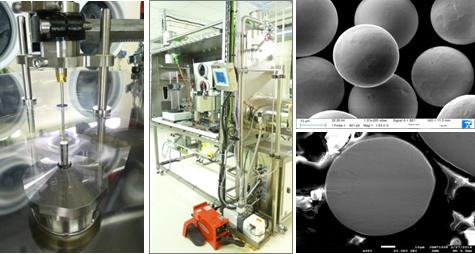

An REP prototype has already been constructed by Framatome (CERCA) and TUM and successfully tested. However, to achieve the desired

production performance, a more complete comprehension of the atomization process has to be achieved. This is part of the UMo atomization

comprehension phase. This phase includes quality studies (droplet formation mechanisms, size distribution, powder shape and surface, atmosphere,

chemical properties), design improvements (scalability, comparison to other prototypes, yield studies, scrap recovery) and modelling activities

to understand the physical mechanisms.

Once a thorough understanding has been achieved, prototype and then commercial equipment will be constructed as outlined above.

A major topic in the comprehension of powder atomization is the casting of the UMo pins which serve as electrodes in the atomization process

and also influence production capacity. The casting of these pins seems to be one of the main technical issues in the whole process and

will also need to be understood thoroughly.

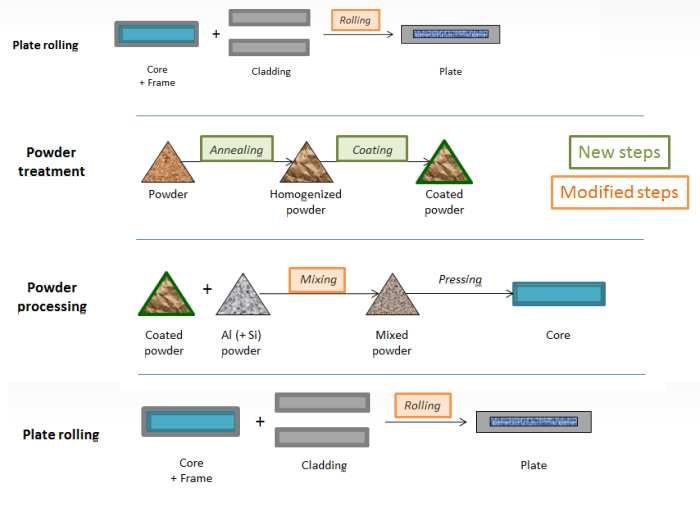

Heat treatment

From the current understanding of the influence on UMo irradiation performance of the microstructure, and of grain size in particular, it seems necessary

to heat-treat the powder prior to fabrication. The goal of the heat treatment is to homogenize the Mo content and to increase the grain size distribution

of the UMo particles as much as possible. This could be achieved by annealing at ~1000°C for several (~2 - 10) hours under vacuum conditions or in an

inert atmosphere. As powder annealing at 1000°C without shaking the powder causes the powder to stick together, a rotating drum (or other agitation process)

needs to be applied inside the furnace. The influence of the heat treatment will be verified by the EMPIrE experiment.

Coating

Five types of powder coating technologies are currently used world-wide for UMo powder coating: Physical Vapor Deposition (PVD) with rotating drum

(SCK-CEN technology), PVD with shaking by oscillating magnet (TUM technology), Chemical Vapor Deposition (CVD) by Atomic Layer Deposition (ALD, ANL technology),

and Chemical Vapor Deposition (CVD) by Fluidised Bed (FB, CEA and INL technology). From the point of irradiation performance, the Fuel Developer Expert Group (FDEG)

has not identified a preferred technology as irradiation data is only available for PVD with rotating drum (SELENIUM campaign), i.e. all technologies are

currently considered as suitable. Therefore, the FMEG has chosen the two most promising candidates for the coating technology in terms of safety,

production quantity, flexibility, costs, design, timing, production yield and maintainability.

As for the powder atomization technology, there will be a comprehension phase for the manufacture of the coating. The comprehension phase will include

a deeper characterization of the existing coatings (SEM, EDX, porosity, shape, thickness, homogeneity, impurities etc.) and an analysis of the

impact of plate manufacture on the coating.

Dispersion plate industrialisation

The production yield for dispersed UMo plate production is currently low for the dispersed UMo plates produced by Framatome (CERCA) in the last 10 years

and needs improvement. The main non-conformities have been ultrasonic defects, uranium homogeneity variations and blisters. The development

of industrialization involves the improvement of production yield to 80%, the achievement of reliable cost and safety conditions, and determining

the level of variability the process can accept to mitigate the risk during the transition to commercial production (cladding material, real plate

format, plate bending). The commercial production foreseen for the HERACLES group reactors after conversion is several thousand plates/year.

For product industrialization, the HERACLES group takes an iterative approach: comprehension phase, pre-industrialization phase, industrialization phase,

and reactor plate geometry testing, in order to reduce the risk when transferring from laboratory to industrial scale. The comprehension phase includes

studies on powder mixing and powder compaction, modelling of plate rolling and plate bending, parametric plate studies and fuel system modifications

(matrix, loading, etc.). The preindustrialization phase will help to determine the final plate specifications, based on the results obtained after

irradiation and manufacture.

The industrialization phase starts after the pre-industrial phase and ends before the MIXED-ELEMENT manufacturing.

Industrialization is a key step towards the successful qualification and subsequent usage of UMo fuels.

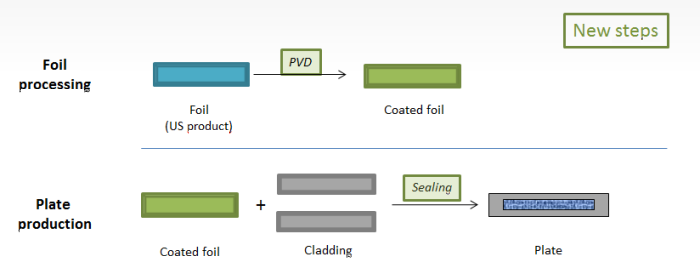

Monolithic fabrication developments

Much of the development work on monolithic UMo-based fuel has been done in the US. However, Europe has always contributed to these developments

in order to build up the necessary production knowledge and to

support the common goal of non-proliferation. Development can

be divided into three major phases: the initial attempts to fabricate foils and plates, the ALPS project which focused on plate

production, and the follow-up project ALPS II which is the current project.

The preliminary European studies were carried out between 2005 and 2008 in a joint project by CEA, CERCA and TUM. At that time the monolithic fuel concept

was being proposed by the US

developers as an alternative to dispersed fuel which had suffered from a series of unsuccessful irradiations.

The intention was to reduce the interaction between aluminium and UMo fuel, considered to be responsible for the

anomalous swelling, by eliminating the matrix from the fuel system. The aim of the project was to establish techniques for

ingot making, foil manufacturing and plate production.

Even though foils could be fabricated, the foil quality obtained was unsatisfactory, inducing cracks and oxidation. Further

difficulties arose in plate fabrication, which performed well using surrogate material but had poor adherence properties with

UMo. As one major result, the C2TWP process ("CEA CERCA TUM Welding Process") emerged from the

experiments, a process which is now regularly used for experimental plate production.

Based on the manufacturing and irradiation results from the US program, it was decided to deposit an

intermediate layer of suitable material between the UMo foil and the cladding. Zr was determined as suitable

material in heavy ion and in-pile irradiations and first attempts were made by TUM to construct devices that were able to

deposit thin Zr layers on foils using PVD techniques. When the US program was reoriented towards monolithic foil and plate

production, the European focus shifted to plate fabrication.

This led to the definition of the ALPS program, which was started in 2008 and conducted by CERCA and TUM in cooperation with the Idaho National Laboratory.

Two options were considered for the intermediate layer, co-rolled foils produced by INL or sputter coating on bare foils. While the first technique is on the way to

industrialisation for plane foils, the PVD technique has much greater flexibility and easily allows for coating of UMo foils with more complex geometries, e.g.

for the foils with thickness variation as required by HFIR and FRM II.

To bring the full-size foils to conformity with irradiation specs, the ALPS II program was launched in early 2014 as a continuation of ALPS.

ALPS II focuses on eliminating the few remaining non-spec-conform non-bonds and on tuning the TUM PVD technique for foil coating.

As before, this will first be achieved using surrogate material, then DU and finally LEU. Irradiation of a sputter-coated monolithic foil processed

by Framatome (CERCA) is foreseen as part of the SEMPER FIDELIS irradiation test.

Graded fuel

Parallel to the developments for the production of plates from plane monolithic foils, studies will be carried out to find a fabrication

strategy for graded foils. Comparably little effort has been put into this by the US fuel manufacturers so far. While the US approach uses

co-extrusion to produce Zr-coated graded UMo foils, the HERACLES approach favours the machining of bare plane foils into the desired

shape followed by sputter coating. This strategy provides a number of advantages, especially in the field of scrap recovery.

However, a number of challenges have to be solved, e.g. machining with the necessary precision of some 10 μm for pyrophoric, radioactive materials.

The HERACLES project on graded UMo foils is scheduled to begin in early 2016, again in close cooperation with the US partners.

The first irradiation test with graded fuel will be the FUTURE-MONO II test.

As with the work on dispersion fuel, the approach towards industry-scale equipment is an evolutionary one, progressing from prototype

(1% of commercial production capacity) to pilot (10% capacity) and commercial (100% capacity) equipment for each technology in order

to reduce the risks in the transfer from laboratory to industrial scale.

Plate industrialisation

As for the industrialization of dispersion plates, HERACLES takes an iterative approach: comprehension phase, pre-industrialization phase

and industrialization phase. The plate geometry for each reactor will then be tested in order to reduce the risks in the transition

to commercial production.

The pre-industrialisation phase again aims at iteratively developing plate specifications and increasing the production yield to more than 80%.

Furthermore, the pre-industrialisation phase will include the production of plates from graded foils. It is therefore scheduled to end with FUTURE-MONO II.

Finally, the aim of the plate industrialization is to produce several batches of full-size plates using graded foils in order to verify that there is no

significant variation using the pilot equipment and to determine the yield (with a goal greater than 80%) and the process stability for graded foils.

The HERACLES Consortium

The HERACLES Consortium