Radioisotopes such as

99Mo save hundreds of lives every day. Yet their production is only one of the multitudes of outstanding and unique services

that the European High Performance Neutron Sources provide for our society. We develop and test new functional materials, provide engineering

solutions to energy, automotive, computational and environmental questions, decipher bio-chemical processes for biology and medicine as well

as offer insights into archaeological artefacts and processes. One unusual, but for us particularly important task, is our support of the

international nuclear non-proliferation efforts by replacing our current fuel with a lower enriched, high density solution.

HERACLES-CP is a

HORIZON 2020 project, supported by the

European Commission, and is a central pillar of the overall fuel development program

of the

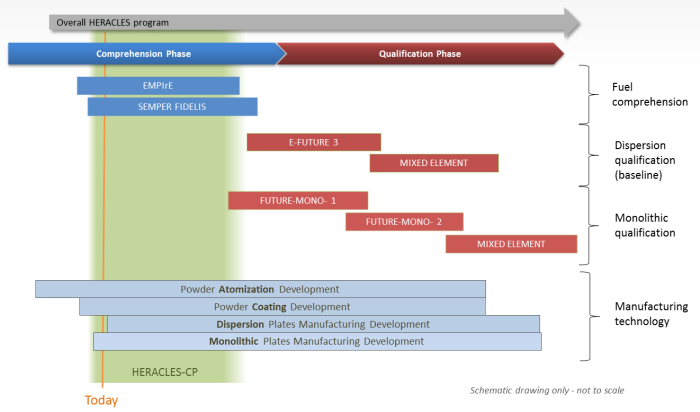

HERACLES group. "CP" means "Comprehension Phase" and lays the scientific foundation for a successful fuel qualification. Only a safe

and reliable high density fuel guarantees that the distinguished performance of our neutron sources will be available in the future for the

greater benefit of society.

Project description

In the framework of the joint international efforts to reduce the risk of proliferation by minimising the use of highly enriched uranium, a new research reactor

fuel based on

uranium-molybdenum (UMo) alloys is being developed by the HERACLES group.

There are two types of UMo fuel - fine particles dispersed in an Al matrix, and monolithic foils. The qualification phase of these fuels

is scheduled to begin in 2019; the CP project will prepare the way with an initial comprehension phase, to improve our understanding of the

fuels'

irradiation behaviour and consequent the manufacturing/industrialisation process. One of the key components in the project is the

SEMPER FIDELIS irradiation test, which aims at investigating the fuel swelling phenomenon and the effects of coating, with a view to

arriving at procedures for fuel engineering.

The challenges as regards

manufacture lie in the basic elements of both fuel types' production process and plate manufacturing.

For the dispersed fuel, this includes the pin casting for the rotating electrode process and the atomization process itself.

For the monolithic fuel, this concerns the development of coating for the foils. All these components are essential to prepare

the fuel qualification phase.

High-performance research reactors are at the start of the supply chain for medical isotopes like

99Mo.

Successful conversion to lower enriched and where possible LEU fuel is therefore a key element in the mitigation

of the risks surrounding the supply of isotopes as demanded by

NFRP 8.

However, the role of the HPRRs is far broader,

as they are providing scientific and engineering solutions to questions of high societal importance.

Objectives

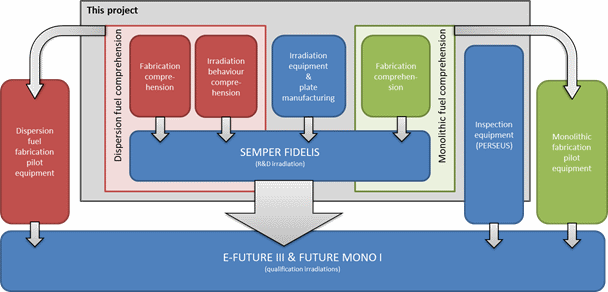

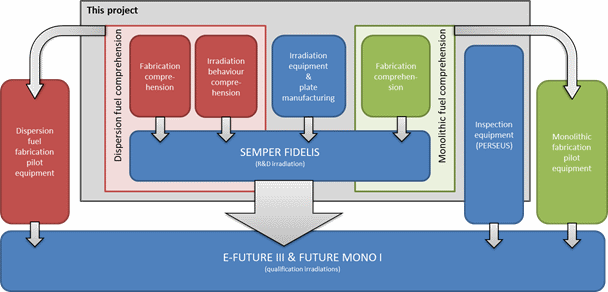

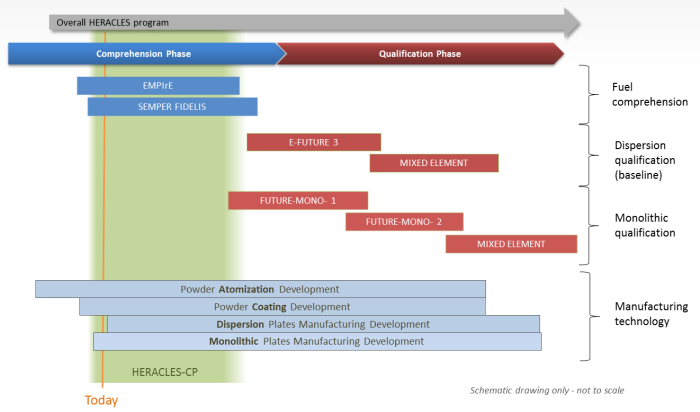

The objective of the programme proposed is (see Figure 1):

- For dispersed fuel:

- To fill the knowledge gaps identified by performing the necessary experiments and measurements,

- To conclude on the most promising fuel design based on the results of these,

- To develop the necessary production techniques and

- To prepare a SEMPER FIDELIS irradiation test to verify the theory and to fill the gaps that require new irradiation data.

- For monolithic fuel:

- To develop the technology and knowledge necessary for fabrication and

- To prepare test samples for the SEMPER FIDELIS irradiation test.

- For both:

- To develop the technology necessary for the irradiation test as well as the tools for analysis,

- To launch and conduct the irradiation test and finally

- To perform the Post-Irradiation Examinations (PIE) of SEMPER FIDELIS

The general objective of this project can be summarized as:

The provision of the technical and scientific foundations for the successful qualification of UMo fuel

Following this stage, the fuel will be qualified according to national regulations in a series of irradiations and finally used in the facilities above according to specific conversion plans.

Work plan - Work packages, deliverables and milestones

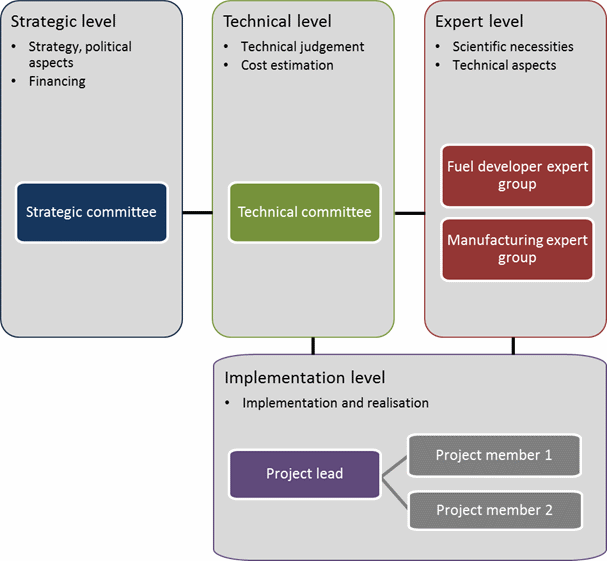

Work package 1: Management

Work package 2: Dispersed fuel comprehension

A thorough understanding of the swelling behaviour of dispersed UMo fuel is one of the most important keys to designing successful qualification

experiments. Therefore, since 2013, a special comprehension program for dispersed UMo has been laid out, including a large number of

experiments that has been described in the full proposal. The objective of this work package is the evaluation of these experiments

in their entirety towards a more thorough understanding of the UMo swelling behaviour. This is an important pillar to support the set-up

of the test-matrix for the SEMPER FIDELIS irradiation test, which will complete the experiments of the core comprehension phase. After that,

all findings from the core comprehension phase will be combined into one report. This report is the foundation for the decision if HERACLES

can directly proceed to a qualification experiment.

Work package 3: Production technology

The aim of the production technology work package is to explore the feasibility of improved technology in a near operational environment.

For this purpose, technology developments, validation on a small-scale prototype and pilot activities aiming to show technical feasibility

in a near to operational environment are performed.

Dispersed fuel:

High density dispersed fuels are produced using atomized powders. TUM and Framatome have already implemented an R&D prototype

of an atomizer at Framatome using the Rotating Electrode Process technology. While the process is working as expected, the R&D prototype induction

furnace used for pin casting is not well adapted and is the main technical issue of the process. Therefore, the work package will focus upon this

induction furnace technology which needs to be adapted to the safety requirement of a Uranium environment in order to be able to manufacture new

adapted R&D pilot equipment.

Monolithic fuel:

The European developments for the monolithic fuel comprise the coating of bare UMo foils by Zr sputtering and the

thickness grading of these foils. While the latter is not in the scope of this proposal, the sputter coating developments of TUM will

be validated by Framatome by producing small-scale prototypes of UMo monolithic plates, called mini-plates or sub-size plates. Framatome will furthermore

study the safety adaptation issues of the technology in order to establish the possibility to implement these technologies in the Framatome workshops.

Work package 4: Powder and plate manufacturing

The powder and plate manufacturing work package aims to establish new knowledge for high density UMo fuel plate manufacturing. For this purpose,

technology developments, testing and validation on small-scale prototypes are performed in a near-to-operational environment.

Comprehension phase:

To improve the fabrication yield, Framatome will perform a comprehension phase to analyze the observed quality insufficiencies and to explain them.

Parametric studies and manufacturing process modeling will be used to improve the understanding of the respective processes and to propose

adapted solutions. The development will start using mini-size plates, will continue using sub-size plates and will finish using full-size plates.

Sub-size plates manufacturing for SEMPER FIDELIS experiment:

At the end of the sub-size plate developments, LEU sub-size plates will be manufactured for the irradiation experiment SEMPER FIDELIS in the

BR2 reactor (WP6). This experiment is the first sub-sized plate experiment in BR2.

Work package 5: Heavy ion irradiations

Heavy ions irradiation is a tool to quickly check many effects of in-pile irradiations on the fuel with comparably little effort

and low costs. Several irradiations are planned to fill data gaps for WP2.

Work package 6: SEMPER FIDELIS in-pile irradiation

The objective of this work package is to test by irradiation in a test reactor the advanced fuel produced according to the design proposed

in WP2 with the advanced manufacturing technology defined in WP3, and implemented in the plates produced in WP4.

The irradiation test is combined with the fresh fuel characterisation. The irradiation and post-irradiation examination

results are intended to yield insight into the phenomena occurring in the high burn-up UMo dispersion fuel, as described in WP2.

The interaction layer formation and the excessive fuel swelling rate encountered in past experiments at high burn-up after a high power

irradiation require further analyses. Mitigation strategies for these phenomena are proposed and assessed within WP2 and then converted

in an appropriate irradiation matrix in order to test the hypotheses and evaluate our understanding of the phenomena and appropriateness of our models.

Work package 7: PERSEUS device

Examination of irradiated fuel elements is crucial for assessing the LEU fuel plate behaviour. A device using two ultrasonic sensors,

radiation resistant, will be developed for such applications. Design studies, modelling, manufacturing and experiments will be carried

out to achieve this.

Additional material

Want to know more?

Download the official HERACLES-CP project presentation as PDF.

This project has received funding from the Euratom research and training programme 2014-2018 under grant agreement No. 661935.

The HERACLES Consortium

The HERACLES Consortium